Quick Connect Couplings Explained: Mastering Fluid Systems

November 22, 2023

Pneumatic Fittings for Industrial Applications: Maximizing Performance

November 27, 2023Understanding Needle Valve : Function and Applications

Needle valves play a crucial role in fluid control systems across various industries. Their precision, reliability, and versatility make them indispensable components in managing the flow of liquids or gases with accuracy. In this detailed exploration, we’ll delve into the inner workings of Needle Valve, focusing on their function, applications, and specific series—BS01/BSA01 and BS03.

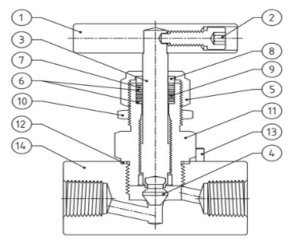

Needle Valves: Unveiling the Mechanism

At their core, needle valves comprise a slender, tapered pin (the “needle”) that fits into a conical seat. This design allows for fine control over the flow rate, granting engineers the ability to regulate flow precisely. By turning the valve handle, the needle is raised or lowered, altering the opening through which fluid passes. This fine adjustment capability makes the needle valve ideal for applications requiring meticulous control over flow rates.

Series BS01/BSA01: Precision in Construction

The BS01/BSA01 series embodies precision engineering and durability. Constructed from robust materials like stainless steel or brass, these valves offer exceptional corrosion resistance, ensuring longevity even in harsh operating conditions. With varying pressure ratings and sizes available, they cater to a wide spectrum of industries, including oil and gas, chemical processing, and instrumentation.

These series stand out for their adaptability. Their design allows for use in high-pressure systems, where accurate flow control is paramount. The versatility of materials used in their construction makes them compatible with an array of fluids, from water and gases to corrosive chemicals.

Series BS03: Versatility and Reliability

On the other hand, the BS03 series excels in versatility and reliability. Crafted with a keen focus on adaptability, these needle valves are engineered to function seamlessly in both low and high-pressure systems. Their compact design makes them an ideal choice for applications where space is limited.

The materials used in the construction of BS03 series valves are carefully selected to ensure optimum performance across diverse environments. From stainless steel to specialized alloys, these valves exhibit exceptional resistance to wear and tear, making them suitable for extended service life.

Applications: Where Needle Valves Shine

The versatility of needle valve extends their application across various industries:

- Instrumentation: Precision instruments often utilize needle valves to ensure accurate measurements and controlled flows.

- Chemical Processing: In chemical plants, where handling corrosive substances is routine, needle valves provide reliable control over fluid movement.

- Oil and Gas: Needle valves find their place in the oil and gas industry, governing the flow of various mediums within high-pressure systems.

- Laboratory Settings: Laboratories leverage the precision of needle valve for controlled dispensing of fluids in experiments and analyses.

Conclusion: Precision in Control

Needle valves, particularly the BS01/BSA01 and BS03 series, epitomize precision and reliability in fluid control systems. Their adaptability to diverse environments, coupled with their ability to provide fine control over flow rates, renders them indispensable across multiple industries.

Understanding the functions and applications of these needle valve series underscores their significance in achieving optimal performance and safety within fluid systems.

Whether it’s regulating flow rates in a complex industrial setup or ensuring precision in laboratory experiments, needle valves stand tall as essential components, offering precision, reliability, and control.

The meticulous engineering behind needle valves continues to shape industries, enabling accurate control over fluid flows and contributing to the efficiency and safety of countless operations.