Understanding Needle Valve : Function and Applications

November 23, 2023

Coupling Pipes: Enhancing Efficiency in Water Distribution Systems

December 4, 2023Pneumatic Fittings for Industrial Applications: Maximizing Performance with Push-On and Push-In Fittings

In the dynamic landscape of industrial operations, the quest for optimization and efficiency remains paramount. Pneumatic systems stand tall as a cornerstone in the machinery-driven world, orchestrating the seamless flow of power and enabling precision in various applications. Within these systems, the significance of Pneumatic Fittings, particularly push-on and push-in fittings, cannot be overstated.

Understanding the Basics: Pneumatic Fittings:

Pneumatic fittings act as the unsung heroes in these systems, forming the essential linkages that ensure proper connectivity between various components. Their primary function revolves around establishing secure, leak-proof connections that facilitate the flow of compressed air or gases within the system. Push-on and push-in fittings, in particular, have gained prominence for their user-friendly nature and efficiency in industrial settings.

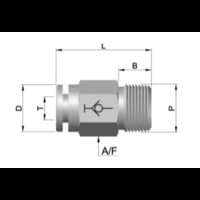

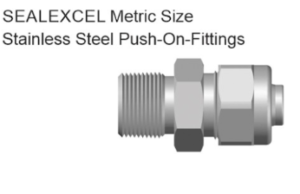

Push-On Fittings: Streamlining Connection Processes:

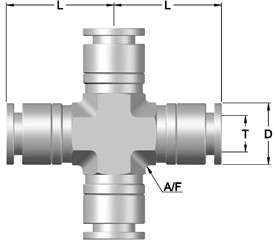

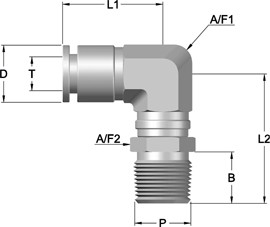

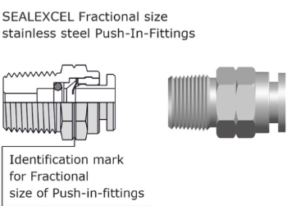

Push-In Fittings: Precision and Reliability

Maximizing Performance: Advantages of Push-On and Push-In Fittings:

- Efficiency in Assembly: The straightforward installation process of these fittings minimizes assembly time, allowing for quicker deployment of pneumatic systems.

- Flexibility and Adaptability: Their user-friendly nature allows for easier modifications or expansions in the system, catering to changing industrial needs.

- Enhanced Reliability: The secure connections offered by these fittings reduce the risks of leaks or system failures, ensuring consistent performance.

- Reduced Downtime: Swift installation and easy maintenance translate to reduced downtime, optimizing productivity in industrial setups.

Applications of Pneumatic Fittings Across Industries:

The versatility of push-on and push-in fittings finds application across diverse industrial sectors. From automotive manufacturing lines to pharmaceutical production facilities, these fittings play a pivotal role in ensuring the smooth operation of pneumatic systems.

In automotive assembly, for instance, these fittings facilitate the functioning of robotic arms, conveyor belts, and other machinery critical in the production process. Their reliability ensures seamless operations, contributing to the precision and efficiency synonymous with modern automotive manufacturing.

Similarly, in pharmaceutical facilities, where precision and cleanliness are paramount, push-on and push-in fittings maintain sterile pneumatic connections, supporting the production of medicines and maintaining stringent quality standards.

Conclusion:

Pneumatic fittings, particularly push-on and push-in variants, stand as indispensable components in the realm of industrial applications. Their ease of use, reliability, and efficiency not only streamline assembly and maintenance processes but also significantly contribute to maximizing performance in diverse industrial settings. Understanding their significance and leveraging their advantages can propel industrial operations towards enhanced productivity and efficiency in the ever-evolving landscape of technology-driven industries.

In the pursuit of optimizing industrial processes, the role of these fittings remains unparalleled, serving as silent yet pivotal contributors to the seamless functionality of pneumatic systems.