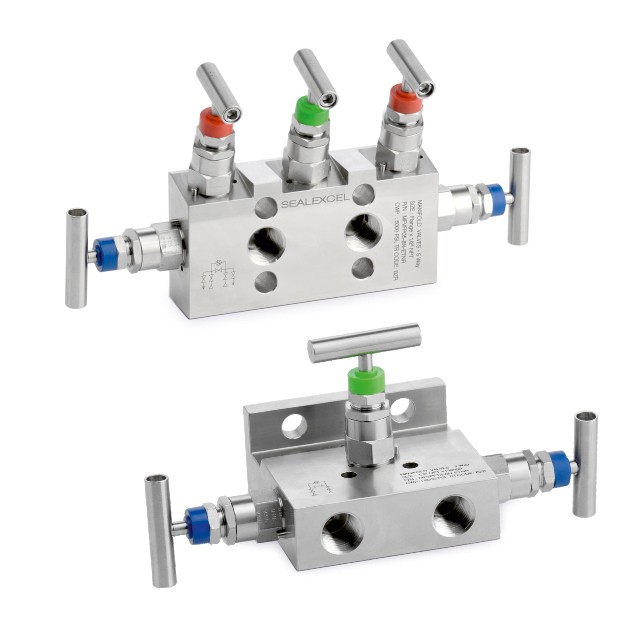

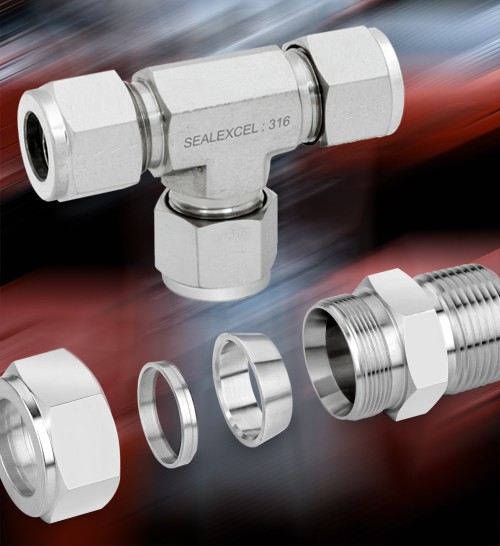

Instrumentation Valves Manufacturer & Supplier

Sealexcel is the market leader in manufacturing and supplying instrumentation valves to a wide gamut of customers. However, we offer the most expensive range of instrumentation valves in today's competitive scenario. We have instrumentation valves in different configurations along with various material and end connection sizes that make us distinctive in the market.

We truly believe in delivering innovative and perfect instrumentation valves. That is why our instrumentation valves are very unique and precise in design that performs well in both low as well as high temperatures. Also, they can perform efficiently in high and low pressure as well through a wide variety of media. We have been taking care of manufacturing world-class instrumentation words that can efficiently perform in very tough operating conditions that include cryogenic operating conditions. However, Sealexcel valves are tailored to meet your every business requirement and will meet the particular needs of your system applications.

Our expert team of professionals is truly attentive towards your requirement and leaves no stone unturned to accomplish product goals. Additionally, each of our instrumentation valves undergoes stringent quality checks before they are delivered to our customers. We possess inherent strength in our well-equipped infrastructure that encompasses advanced machines along with experienced and talented supervisors engineers staff workers who constantly strive to excellently perform in their respective domains. Additionally, our factory is well equipped with modern CNC as well as conventional machines. However, our testing procedures make use of cutting-edge equipment and include pneumatic testing, hardness testing, and other types of quality testing.

We have been the top leading instrumentation valve manufacturer in India who strongly believes in high-performance reliability and great value. You can contact us anytime and our expert team will always be there to guide you in choosing the perfect instrumentation valve for your business requirement.

"