Stainless Steel Push-in-Fittings

Application

SEALEXCEL® Stainless Steel Push-in-Fittings are resistance to aggressive environments and corrosive fluids etc., which are generally used in Chemical, Food, Printing, Packaging, marine Pharmaceutical Industries etc., SEALEXCEL® Stainless Steel Push-in-Fittings are compatible with,

- Semi-rigid nylon tube

- Flexible polyurethane tube

- Low density polyethylene tube

- Fluoropolymer FEP140 tube

- Stainless Steel and copper tube (when grooved)

Design

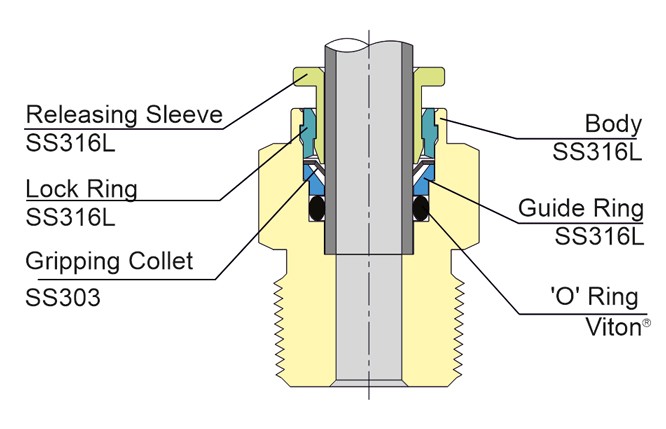

SEALEXCEL® Stainless Steel Push-in-Fittings consist of Six precision components such as Body, Releasing Sleeve, Washer, Gripping Collet, Guide Ring and 'O' Ring.

These components have been carefully designed and manufactured to very stringent tolerances under rigid quality control procedures approved to ISO 9001:2015 to provide a zero leak at all tubing connection in Instrumentation and process tubing.

Advantages

SEALEXCEL® Stainless Steel Push-in-Fittings are,

- Easy for manual connection and disconnection.

- No tools required for connection and disconnection.

- Full Flow without pressure drop.

- Automatic tube sealing with 'O' Ring and locking with gripping collet.

Surface Treatment

Each and every Stainless Steel components of SEALEXCEL Push-in-fittings are electropolished to ensure a corrosion resistant surface layer of chromium oxide which is passive.

Operating Parameters

Pressure: upto 290 PSI (20 bar)

Vacuum: -750 mm of Hg i.e. 98%

Temperature: upto 150ºC

Available Sizes

Metric size ranges from : 4mm through 16mm Tube ODFractional size ranges from : 3/16” through 5/8” Tube OD.

Recommended tolerance on tube ±0.05 mm

Material of Constructions

a) SS-316 BAR STOCK : ASTM A-479

b) SS-316 FORGING : ASTM A-182

Identifications

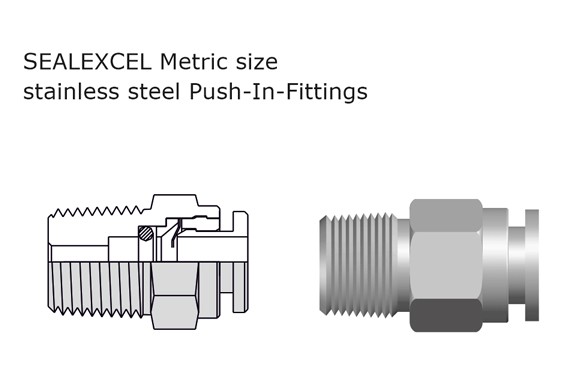

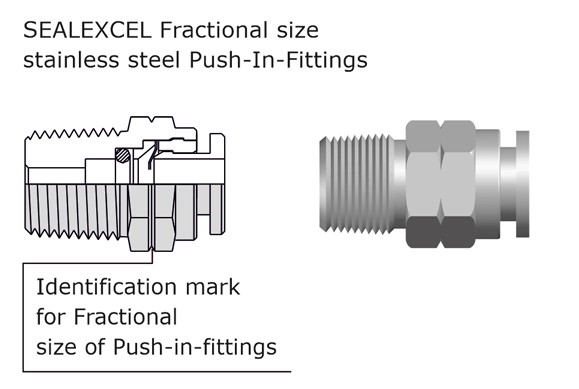

SEALEXCEL® Metric and Fractional size Stainless Steel Push-in-Fittings are similar in appearances.The significant difference is in the internal diameter of the Push-in-Fittings components, hence for easy identifications between metric and fractional sizes. SEALEXCEL provided 'V' Groove on Fractional sizes Push-in-Fittings as shown below